Implementing Spc On Shop Floor

Difficulty in implementing spc and other six sigma tools.

Implementing spc on shop floor. Introduction to statistical process control spc and this website. It wasn t long though before he started uncovering some bad news. Management has to justify its goals for implementing an spc software system before it can expect personnel on the shop floor to accept and use it. Define the business need for spc.

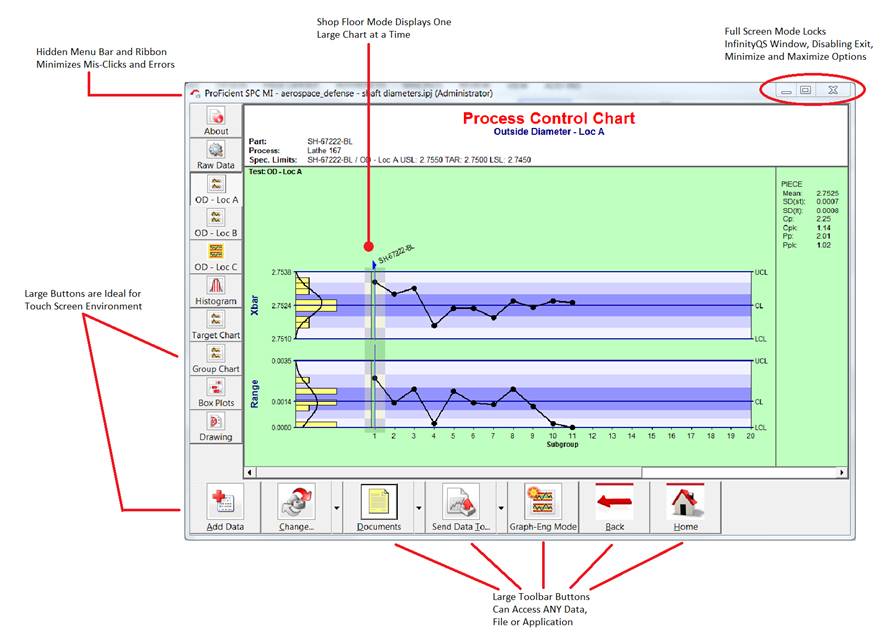

Bob was hired as an spc shop floor leader. When implementing spc it is important that people are. Are you concerned with the lack of computer skills by those who will be using the software. Implement shopfloor online s spc analysis module in combination with the quality module to.

Attached underlayment spc vinyl floors may or may not come with attached underlayment. Management has to justify its goals for implementing an spc software system before it can expect personnel on the shop floor to accept and use it. Integrate seamlessly into your business providing data for everything from shop floor operations and morning meetings to full management reviews and continuous improvement decisions be sustainable with you maintaining the master data. In the beginning bob found his spc coordinator position challenging and interesting.

It is the responsibility of management to allow operators to work with the best methods the best machines etc. This is why your organization needs to have pre project meetings and reviews with the shop floor experts to try to minimize these issues before they happen. Infinityqs software is specifically designed to make data collection a breeze even in challenging or harsh. This layer is waterproof and will contain the pattern texture and look of the floor.

And the ability to manage the system when new products come on line without going back to the supplier. These are usually included to help with sound reduction and add softness to the floor. Clearly defining and communicating the reasons for the spc software up front will go a long way in engaging the front line stakeholders particularly with operators who have experienced prior quality initiatives that did not receive shop floor support. I am going to just briefly touch on this here and write a full length article about it at a later date.

With this shop floor involvement in mind here are six ways to promote engagement of and support by shop floor personnel when implementing a new spc software system. You want to get buy in from the people who will be implementing your spc system usually the it team but more importantly the people who will be using your system the shop floor operators. Obtain real time spc analysis to ensure your process is stable react faster when process abnormalities arise measure process capability and produce capability reports. His job was to work on the shop floor specifically to implement spc and oversee its success.

These two groups of people are crucial to the success of the psychological phase of your spc implementation so you need them to be fully onboard with the program.