Injection Moulding Vinyl Release Air

Large selection of sizes and styles in stock and ready to ship.

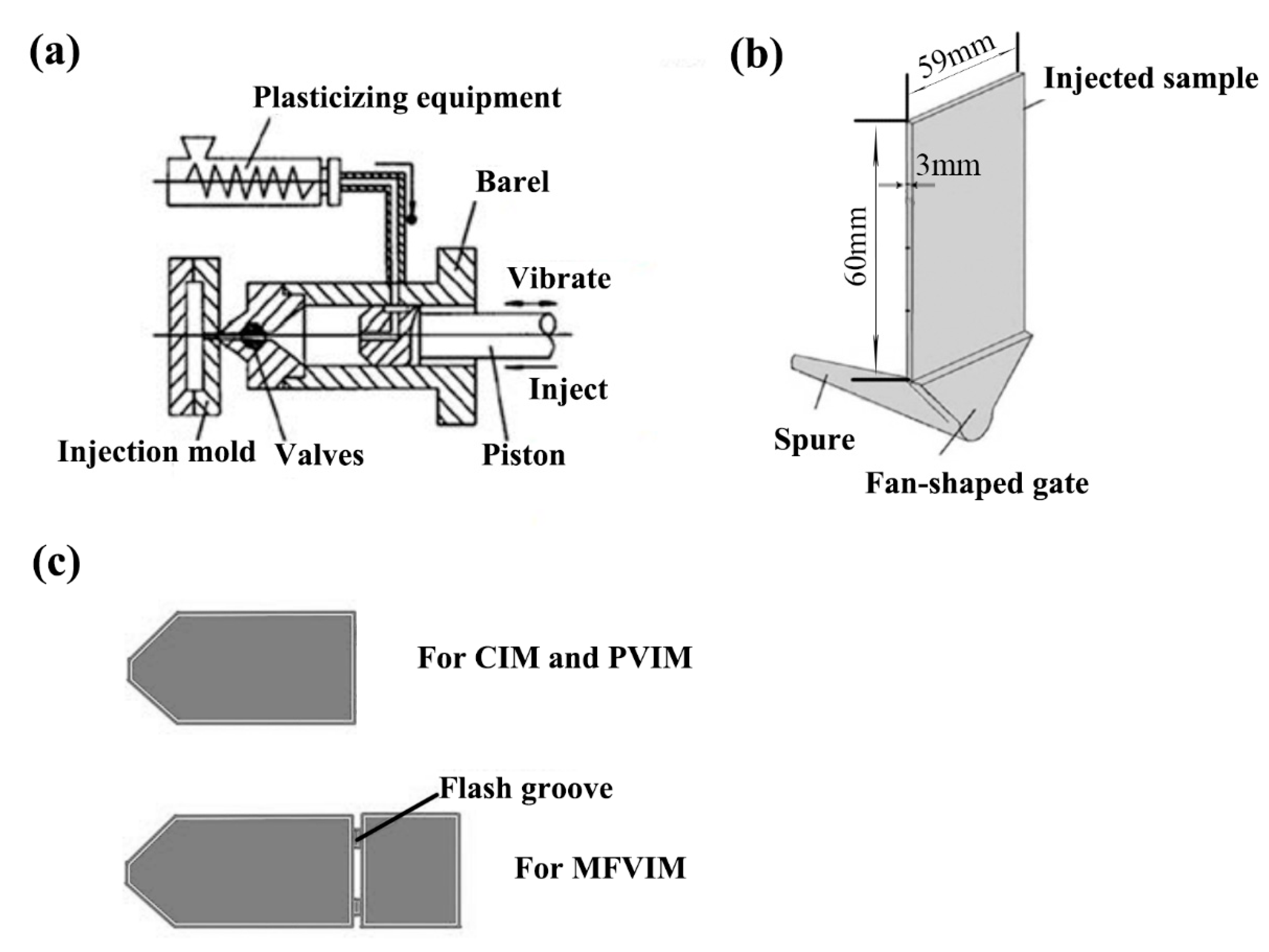

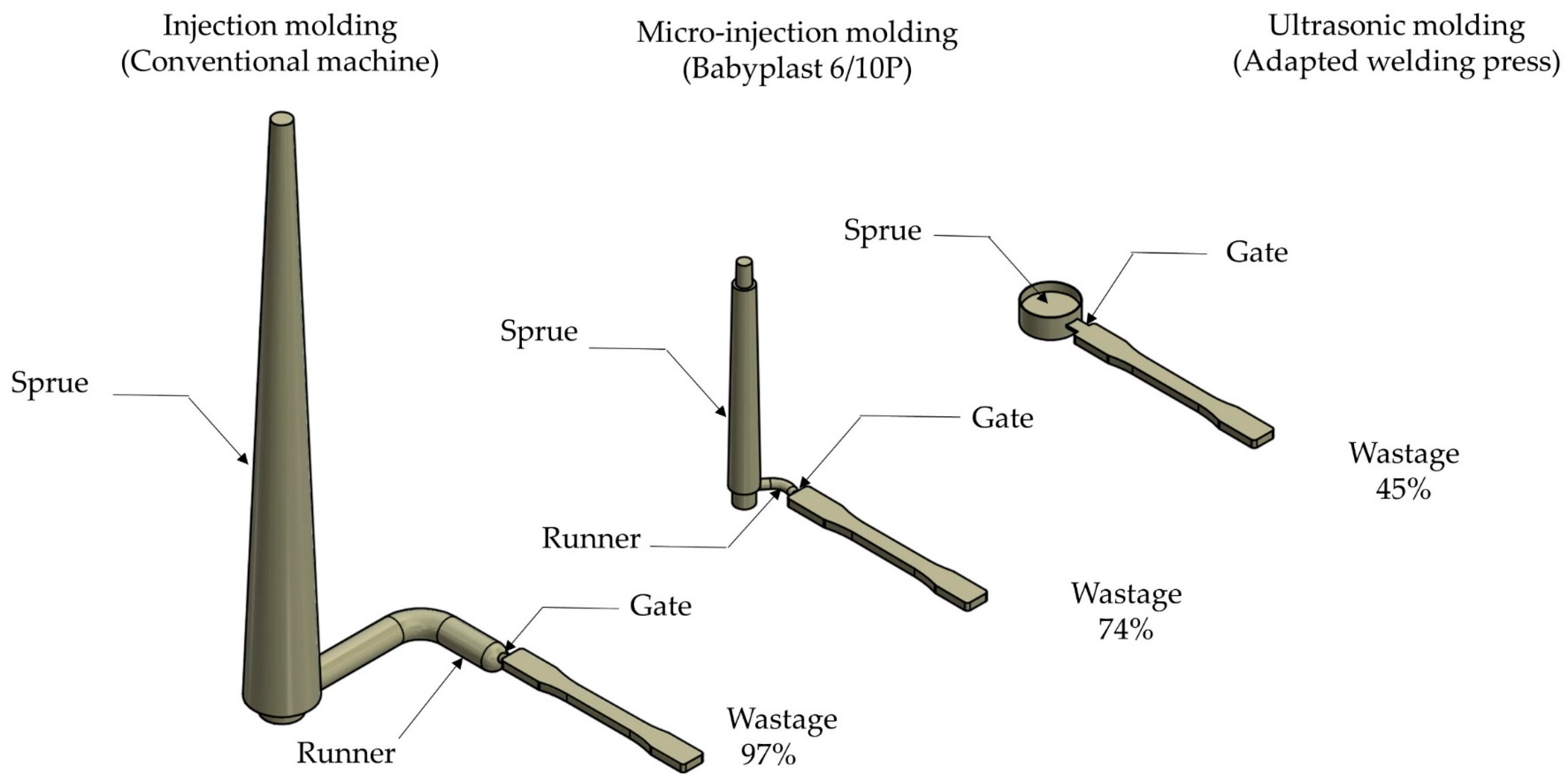

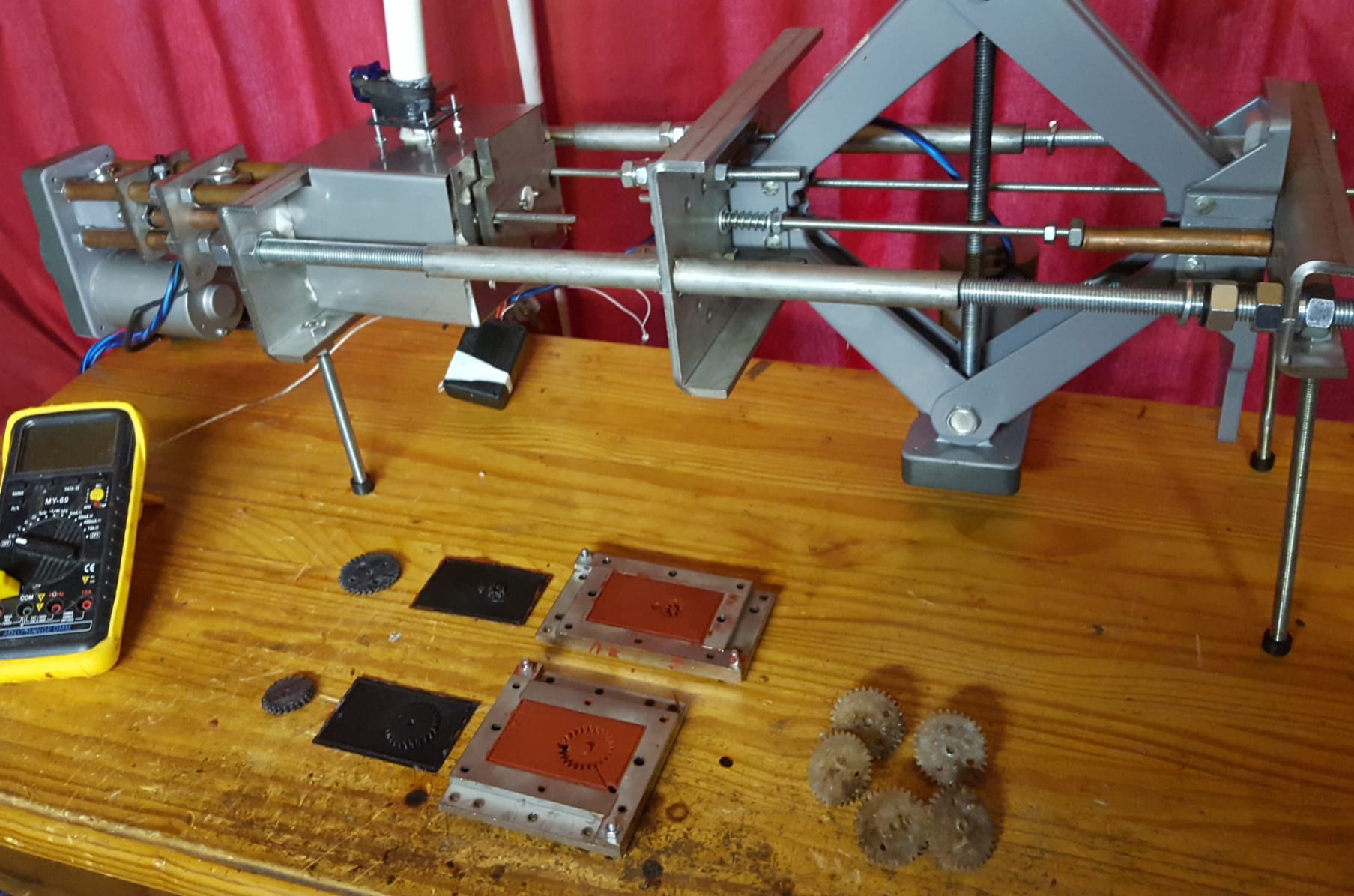

Injection moulding vinyl release air. Injection molding is a manufacturing process for producing parts by injecting molten material into a mould or mold injection moulding can be performed with a host of materials mainly including metals for which the process is called die casting glasses elastomers confections and most commonly thermoplastic and thermosetting polymers. View our wide selection of plastic and rubber products including caps plugs handle grips tube plugs hole plugs high temp tapes and our molding services. 31 a semi permanent water based mold release agent is used for composite materials e g graphite containing fuselage or wings parts. The melted plastic is injected into a metal mould by a reciprocating screw.

Moreover the injection molding products are accurate in size easy to be replaced and the mold parts can be formed into complex shapes. Pellets or granules are loaded into a hopper and heated in a barrel. Homeland vinyl products inc. Mocap manufactures quality plastic and rubber components for product protection masking and finishing.

Polyurethane pur and pu is a polymer composed of organic units joined by carbamate urethane links. The parts are held under pressure until cool then removed and trimmed. Silicone mold release agents have been a staple in the molding industry for over 60 years. In handbook of antiblocking release and slip additives third edition 2014.

The advantages of plastic injection molding for manufacturing parts methods include fast production speed high efficiency automation of operation shapes and size flexibility. While most polyurethanes are thermosetting polymers that do not melt when heated thermoplastic polyurethanes are also available. 225 f 107 c 446 f 230 c 475 f 246 c 600 f 316 c painting air dry. The mold release agent comprises a functional siloxane a crosslinker a thickening agent a base and water.

In this process workers may be exposed to heated resins release agents and cleaning solvents. Sticky parts were the status quo during the infancy of the molding industry and even as technology has evolved and mold design and mold making materials have improved mold release agents still play a significant roll in improving cycle times and helping. All flexible pvc injection molding compounds are formulated and produced to process consistently from lot to lot through our customer s equipment. Polyurethane polymers are traditionally and most commonly formed by reacting a di or triisocyanate with a polyol since polyurethanes contain two types of.

Painting with bake up to 350 will withstand. Injection molding vinyl compounds. Buy plastic caps and plugs online direct from the manufacturer.