Installing Vinyl Wall Base Inside Corners

Set the saw angle.

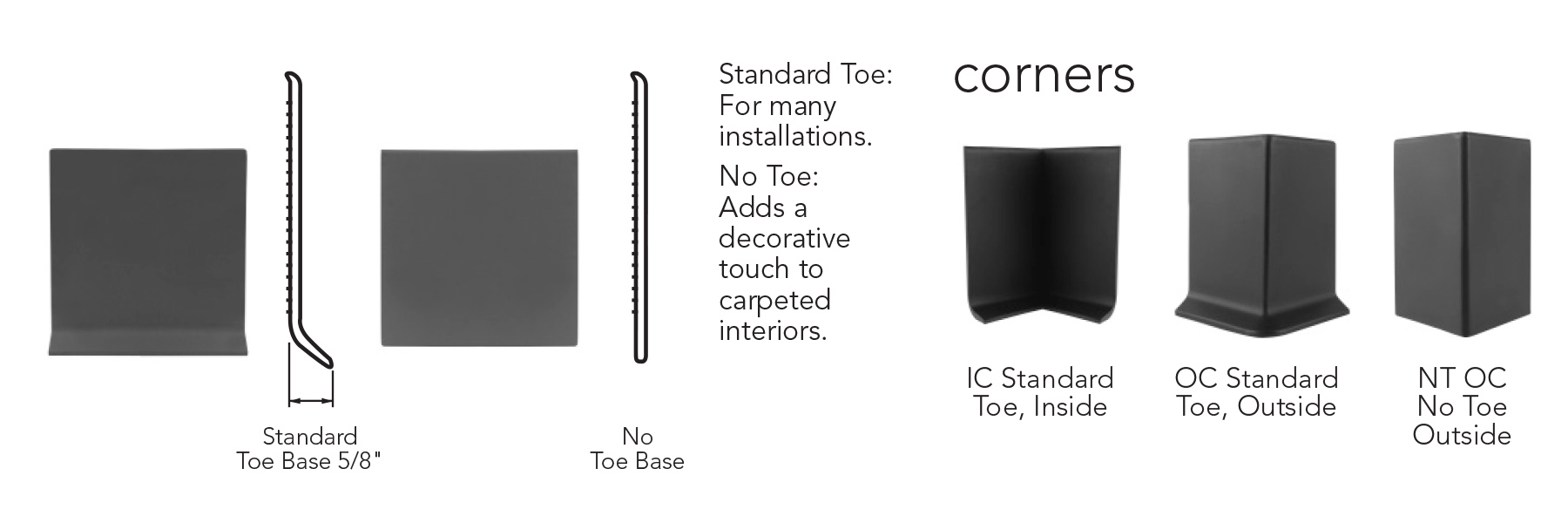

Installing vinyl wall base inside corners. These vinyl baseboard corners will be 4 tall 080 thick and 1 in length. Wash the walls degrease any problem spots then hold the flat vinyl along the wall to mark cuts and corners before removing the adhesive backing. Installing vinyl wall base can add the perfect finished touch to most rooms but corners can often be tricky. Move the miter saw s blade to an angle just slightly less than 45 degrees to the back fence.

Press the vinyl against the wall and flush on the floor as you work down the wall. Steps to install vinyl wall base. While it might seem as though 45 degrees is the perfect angle to achieve 90 degree corners just a hair a fraction less than 45 degrees but no less than 44 degrees produces a better fit when you fit the two adjoining pieces of baseboard. It may help to scribe a light line on the wall that you can line up the top edge of the molding with as you go to ensure a straight application.

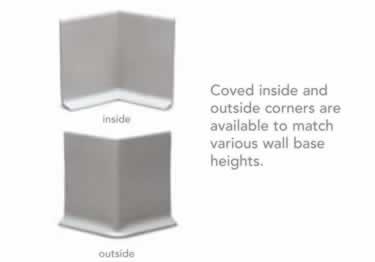

Stick on baseboard requires completely clean walls to ensure the vinyl clings to the walls. Unroll the roll of vinyl wall base the length of the wall in order to estimate the length. Vinyl wall base installation approved adhesive for porous substrates 1100 wall base adhesive approved adhesive for non porous substrates use a premium contact adhesive for the application of vinyl wall base pre molded factory corners or inside outside rubber corner or micro corner blocks on non porous substrates. A cove base is a great way to add a distinctive touch to any wall.

With the ease of installation this is a good project for anyone to try. 4 inside cove base corners johnsonite vinyl baseboard corners. A rubber wall base or a cove base as it is sometimes referred to if it has an extended toe in front is a rubber molding that begins at the floor and covers a. Butt the end of the roll up to the wall.

How to install a rubber wall base. Wall base vinyl pre molded inside cove base corners will simplify your next installation project. They resist scuffs look great and are very easy to clean. Working with inside corners.

On the side that will make an inside corner use your speed square to cut the toe of the base at a 45 degree angle. For inside corners butt one end of the molding straight into the corner. Cut with utility knife.